Ask This Old House Season 23 Episode 6: When Drainage Meets Determination

A practical exploration of Season 23 Episode 6 featuring Jenn's drainage solutions, Kevin Cradock's carpentry showcase, and Heath's ceiling fan installation with proper electrical safety.

Jenn's Drainage Deep Dive

The episode opened with Jenn Nawada tackling Lauren's water woes—a classic homeowner nightmare involving basement flooding and icy sidewalks from poorly managed gutter runoff. As I suspected from the setup, this was going to be a digging problem more than anything else. The solution involved installing a dry well with a catch basin for the front downspout and a pop-up emitter for the back.

What struck me most was the sheer amount of excavation required. Despite the pleasant on-screen dynamic between Jenn and Lauren, I couldn't help but notice the sweat on Jenn's face and wonder about the army of off-camera laborers who surely handled most of the heavy lifting. A 36-by-40-inch hole doesn't dig itself, and while the show makes it look manageable, anyone who's tackled serious drainage work knows it's backbreaking labor.

The timing couldn't have been better when it started pouring rain mid-project. Whether planned or pure luck, seeing the water rush through the exposed pipes provided a perfect real-world test of the system. It's one thing to talk about drainage theory; it's another to watch your solution handle actual storm water in real time.

The technical approach was sound—using solid PVC pipe rather than perforated to get water away from the foundation first, then allowing it to disperse safely through the dry well system. For similar projects, you'd want components like the NDS 50 Gal. Flo Stormwater Dry Well that Jenn used, along with the NDS Downspout Adapter for the connection. The 4 in. PVC 90-degree elbow fitting and 10ft. PVC solid schedule 40 pipe handle the underground routing, while the NDS 422G Pop-Up Drainage Emitter with Elbow is that clever piece of engineering that only opens under water pressure, preventing debris from clogging the system when not in use.

Kevin Cradock's Carpentry Showcase

The spotlight segment on Kevin Cradock Builders felt like a breath of fresh air. Kevin Cradock himself cut quite a figure with his bold aviator spectacles and slicked-back hair—I wonder how many 70s retro revival homes he's built. The dynamic between him and lead carpenter Lasana Harper demonstrated the kind of mentorship that keeps skilled trades thriving.

What impressed me most was their four-stage apprenticeship program. Too often, young people interested in trades face a confusing landscape with no clear path forward. Having a structured program that takes someone from complete beginner to skilled carpenter in four years is exactly what the industry needs.

The relationship between Lasana and apprentice Eric Coughlin highlighted something often overlooked in trade education: the importance of patience and creating space for questions. As Lasana noted, he tries to let apprentices work through problems themselves rather than jumping in to demonstrate. That kind of restraint takes real skill as a teacher.

I did notice they glossed over some of the traditional aspects of apprenticeships—the hazing, the grunt work, the personality conflicts that can make or break a young tradesperson. But perhaps that's evolving too, and programs like Cradock's represent a more supportive approach to skills development.

Heath's Fan Installation Adventure

The ceiling fan segment with Heath Eastman started predictably enough—an outdated fan in a 1980s addition that needed proper support. But what made this interesting was the discovery that the existing box was mounted to strapping rather than joists, held in place only by resting against the side of a joist. That's the kind of find that makes you question what other surprises might be lurking in your walls.

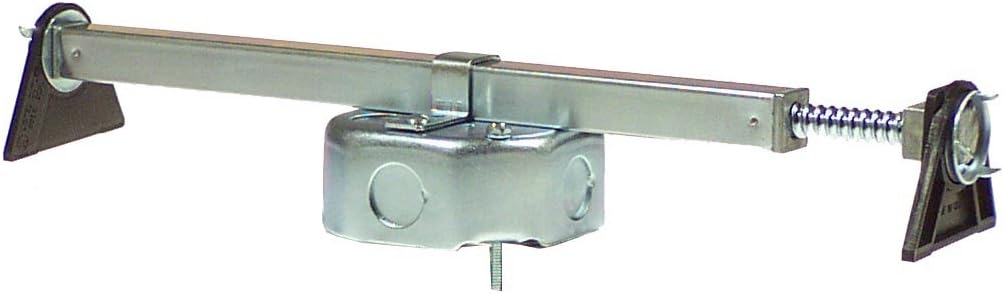

Heath's initial plan to use a Westinghouse Saf-T-Brace got derailed by the tight spacing, leading to a more traditional solution: a 2x6 block between joists with a proper octagonal fan box. Having attic access made this repair almost embarrassingly straightforward—it's like having a cheat code for ceiling work.

The most valuable lesson came from Heath's explanation of proper wiring sequence. The hot wire is black, the neutral wire is white, and the ground wire color is green, and there's a specific order for disconnecting and reconnecting them. When disconnecting, you remove hot (black) first, then neutral (white), then ground (green). When reconnecting, you reverse the order: ground first, neutral second, hot last.

This sequence exists for safety reasons. The ground, green-colored wire is the safety wire to provide a path of electricity when any metal parts touch the hot or neutral wire, while the neutral wire is part of the normal flow of current, while the ground wire is a safety measure in case the hot wire comes in contact with the metal casing of an appliance or other shock hazard. By connecting ground first and disconnecting hot first, you minimize the risk of electrical shock during the work.

Personal note: I replaced a ceiling fan in our house a few years back and was quite proud of the result. Three years later, I realized we never actually use the fan. Sometimes the most successful home improvement project is the one you don't need to do.

Final Thoughts

This episode reminded me why Ask This Old House remains essential viewing for DIYers. While the projects weren't groundbreaking, the attention to proper technique and safety makes the difference between a job that works and one that works safely for decades.

The drainage work highlighted how much success in home improvement depends on your tolerance for hard physical labor. The ceiling fan installation showed that having the right access (like that attic) can transform a complex job into a manageable one. And the carpentry segment reminded us that skilled trades require not just technical knowledge but the ability to pass that knowledge on to the next generation.

Whether you're dealing with wet basements, wobbly fans, or wondering if there's a future in carpentry, this episode delivered practical solutions with the kind of expertise that makes you trust the process—even when it involves digging a very large hole in your front yard.

For quality ceiling fan support hardware, check out this Westinghouse Saf-T-Brace that provides proper mounting between joists.

Related Episodes

Ask This Old House Season 23 Episode 5: Medicine Cabinets, Chimney Crowns, and Time Capsules

A deep dive into Season 23 Episode 5 featuring Nathan Gilbert's medicine cabinet installation, Mark McCullough's chimney crown replacement, and the fascinating world of construction time capsules.

Ask This Old House Season 23 Episode 4: When Paint Jobs Go Right (And Combination Squares Go Missing)

A heartfelt exploration of Season 23 Episode 4 featuring Mauro's bulkhead transformation, Tom's combination square masterclass, and Mark's masonry magic on deteriorating stone steps.

Ask This Old House Season 23 Episode 3: Fruit Trees, Roof Tools, and Smart Lighting

A journey to Florida for tropical gardening, a clever roofing tool that solves real problems, and practical guidance for smart lighting upgrades in your home.